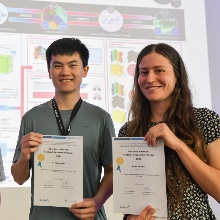

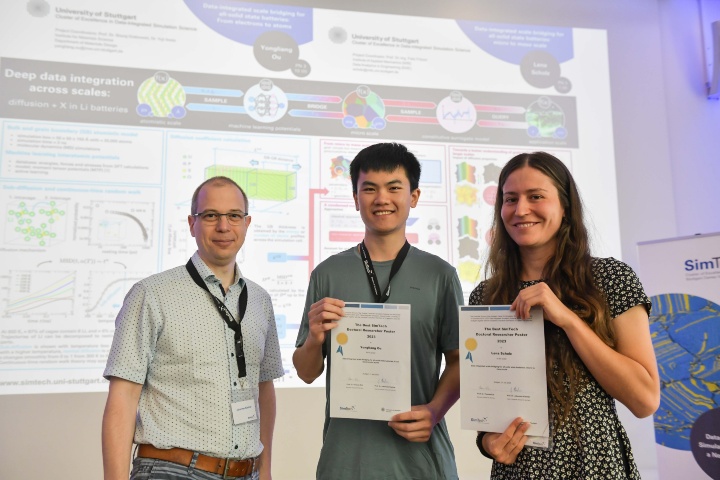

Yongliang Ou, doctoral researcher from the Institute for Materials Science (Department of Materials Design) and Lena Scholz, doctoral researcher from the Institute of Applied Mechanics (Working Group Data Analytics in Engineering) received this year's best poster award for their common presentaion of the projects "from electrons to atoms" and "micro to meso scale" in data-integrated scale bridging for all-solid state batteries. They convinced the voters with quality in content and layout and the interdisciplinarity of their projects. Congratulations!!!

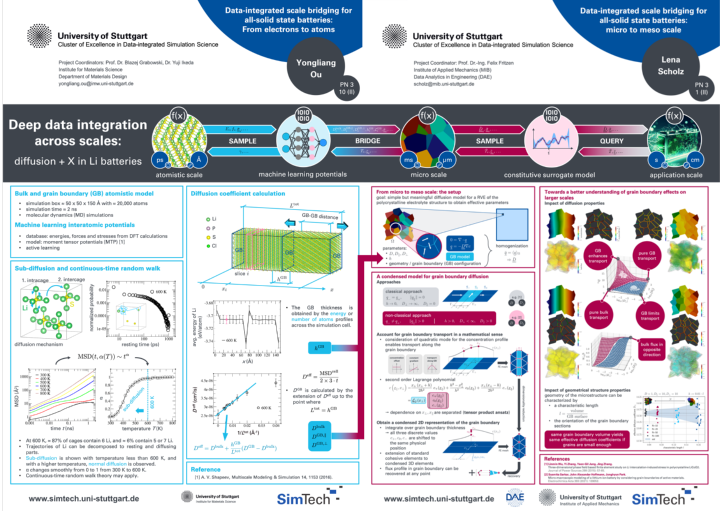

Within their project, Yongliang and Lena aim to design new fast-conducting electrolyte materials with increased safety properties. This requires a better understanding of the complex diffusion behavior accounting for the material’s polycrystalline structure as well as external effects such as temperature and mechanical loadings. To this end, a simulation model which combines a wide range of both time and length scales needs to be constructed.

On the smallest atomistic scale, Yongliang starts from the so-called ab initial simulations based on density functional theory (DFT). Then, machine-learning interatomic potentials are fitted and used to enlarge the simulation scale in space and time, which enables the inclusion of common defects in materials, e.g., grain boundaries. By molecular dynamics (MD) simulations, precise structure and diffusion data are obtained and passed to Lena.

Lena is working on micro and meso scale models to bridge the gap between atomistic scale and actual applications. Here, the material is considered as a continuum with multiple grains rather than distinguishing between the individual atoms. A new type of grain boundary model allows to quantify the effective diffusion properties on application scale using the atomistic parameters that Yongliang has determined. Therefore, the impact of, e.g., grain boundary orientations and material parameters on the application scale behavior can be directly investigated.

However, going all the way from the smallest to the largest scale leads to pronounced computational cost and is in general not feasible if the full complexity of the five-dimensional grain boundary space and temperature effects should be considered. Hence, data-based physics-augmented or -aware models are seen as the most promising candidates for a systematic construction of the material model at the grain boundaries. Further, these models can provide initial guesses based on the current data alongside uncertainty of the model’s predictions. The latter will then allow for the enrichment of the input data in an adaptive scheme. Eventually such a model will then enable the systematic investigation of the impact of, e.g., grain boundary orientations, crystal orientation distribution function (CODF), temperature and grain morphology on the Lithium diffusion.

The project aligns perfectly with SimTech’s vision of bringing together different disciplines, methods and scales to enable next level insights: By allowing for better understanding of the diffusion the tandem project will contribute to the development of safe battery storage solutions in terms of all-solid-state batteries by facilitating virtual material design.