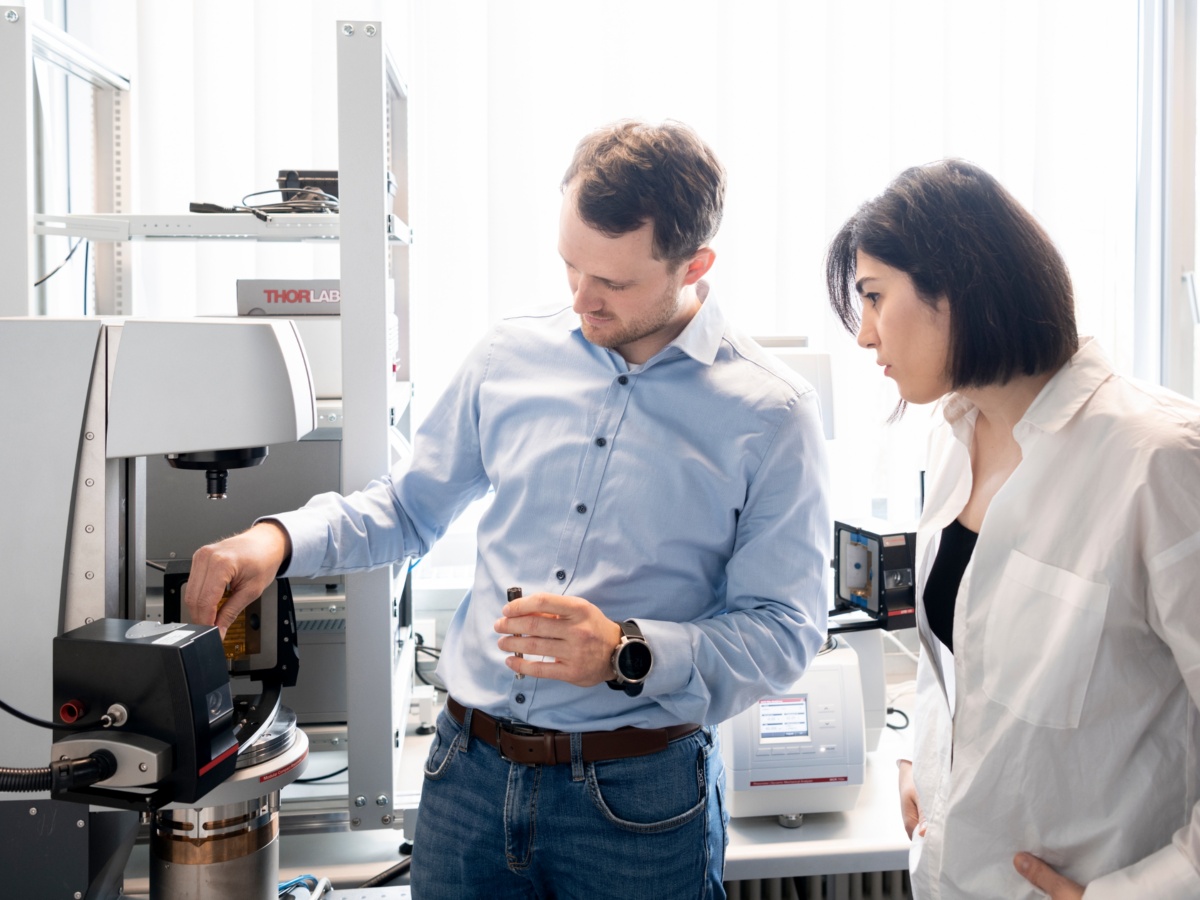

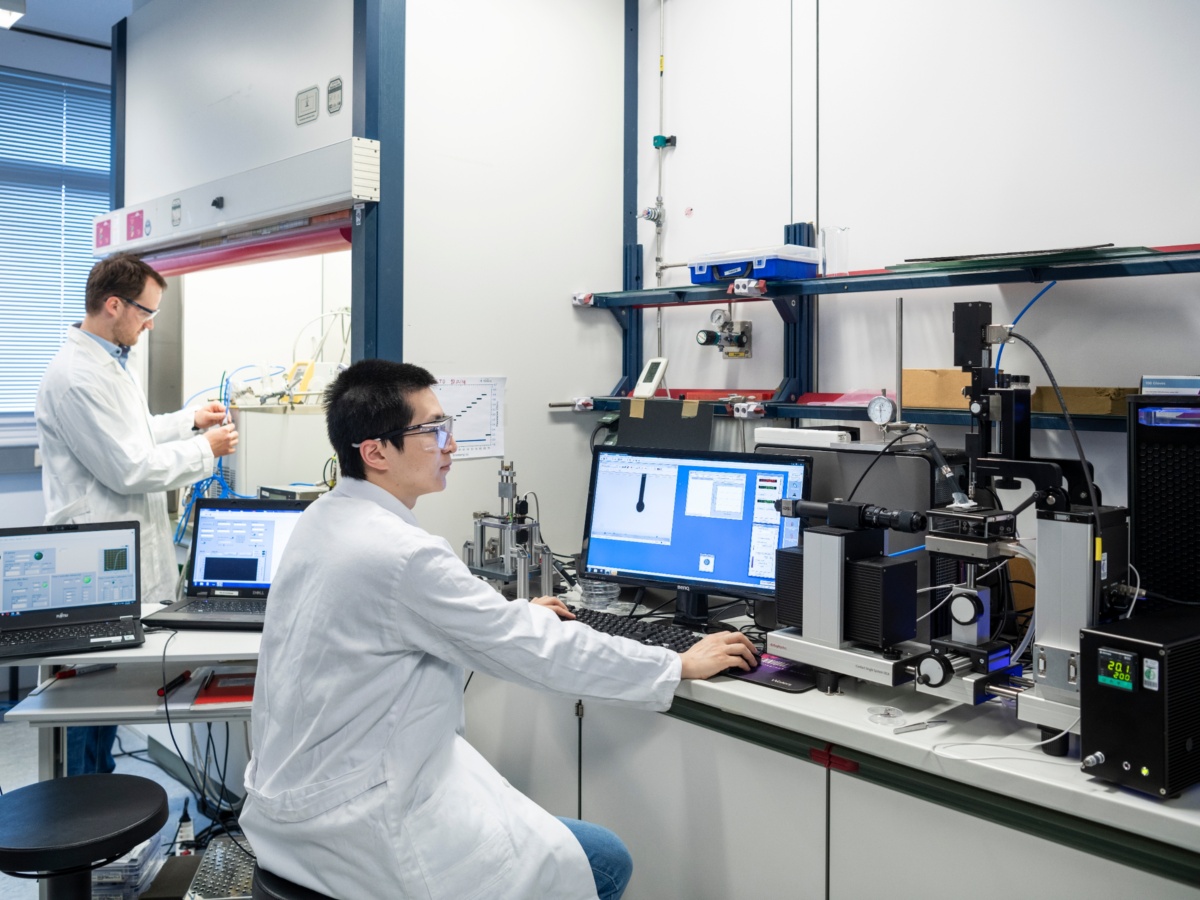

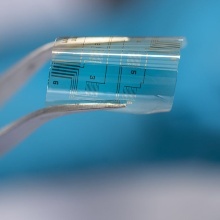

In the framework of the inter-facultary Lab for Functional Soft Materials led by Prof. Sabine Ludwigs (polymer materials science and chemistry) und Prof. Holger Steeb (rheology, material modelling and simulation) we are working on intelligent adaptive materials, which are applicable in Soft Robotics and biomedical applications at the interface between human and artificial material.

We are a novel experimental platform in SimTech which works in a feedback-loop between preparation of novel multifunctional materials, (in-situ) characterization of their functional (e.g. optical and electronic) properties and their mechanical behavior, and multiscale-modelling which allows to predict material behavior based on advanced (data-integrated) numerical simulations.

Our expertise is on intelligent materials which can adapt to environmental conditions and triggered by external stimuli such as temperature, relative humidity and electric fields.